Metal Castings: Overcoming Common Defects in Production

Whatever You Need to Understand About Aluminum Castings: Facts, Advantages, and Solutions Offered

Aluminum castings are essential to modern production, supplying a combination of light-weight and resilience. They are utilized throughout numerous markets, from auto to aerospace. Recognizing the casting benefits, procedures, and applications is necessary for anybody included in manufacturing. In addition, the choice of light weight aluminum alloys and quality assurance measures play a significant function in performance. Discovering these elements reveals much about the future of light weight aluminum spreading solutions and their evolving influence on sector requirements.

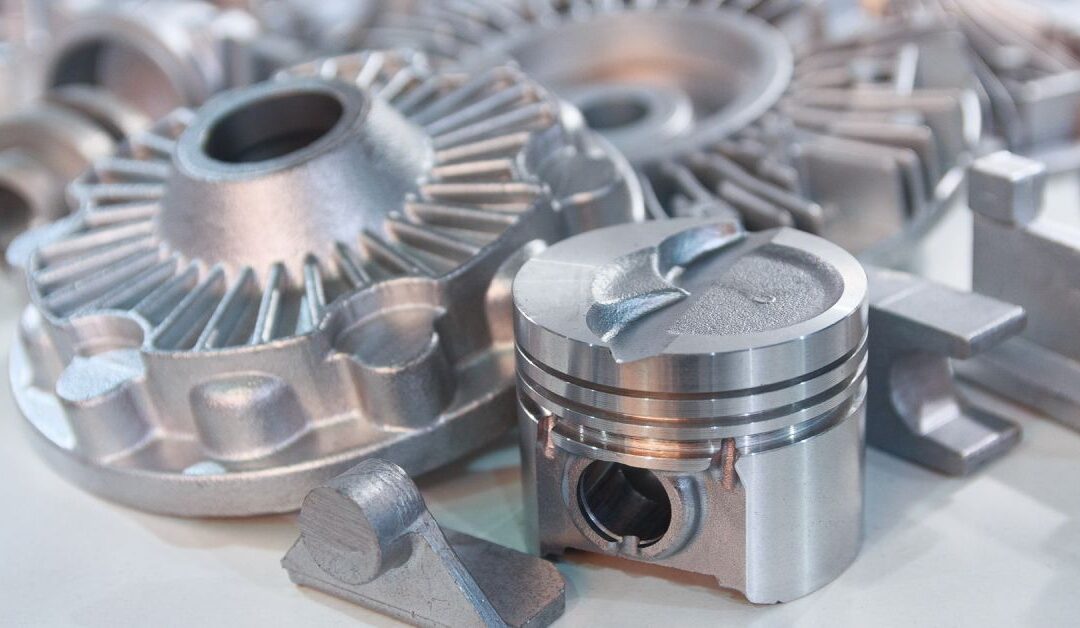

Introduction of Light Weight Aluminum Casting Processes

Light weight aluminum casting processes represent a critical sector of production, enabling the production of intricate forms and elements with high dimensional accuracy. These procedures include numerous methods, such as sand spreading, pass away casting, and investment spreading, each customized to particular applications and requirements. Sand casting involves creating a mold from sand and is ideal for big components, while die spreading uses high-pressure shot of molten light weight aluminum right into metal molds for accurate, high-volume manufacturing. Financial investment casting, on the other hand, uses elaborate layouts by developing a wax pattern covered with a ceramic shell.

Additionally, the selection of spreading approach depends on variables like the desired surface area finish, quantity of production, and product properties. Each method provides one-of-a-kind obstacles and benefits, affecting the end product's high quality and performance. Recognizing these processes is crucial for makers intending to fulfill particular market requirements and accomplish functional effectiveness.

Secret Advantages of Aluminum Castings

The benefits of aluminum spreadings are significant, making them a recommended selection in various markets. One major benefit is their lightweight nature, which adds to lowered transport prices and improved gas effectiveness in applications such as automotive and aerospace. In addition, aluminum possesses outstanding deterioration resistance, extending the life expectancy of components and lowering upkeep requirements.

Aluminum spreadings also show excellent thermal and electrical conductivity, making them suitable for applications calling for effective warm dissipation or electric transmission. The product's malleability permits for intricate styles, making it possible for manufacturers to create complex shapes with precision.

Light weight aluminum castings can be conveniently recycled, advertising sustainability and lowering environmental impact. The quick manufacturing prices connected with aluminum casting procedures boost total performance, enabling quicker time-to-market for items. With these advantages, aluminum spreadings remain an essential option for producers intending for high efficiency and dependability in their offerings.

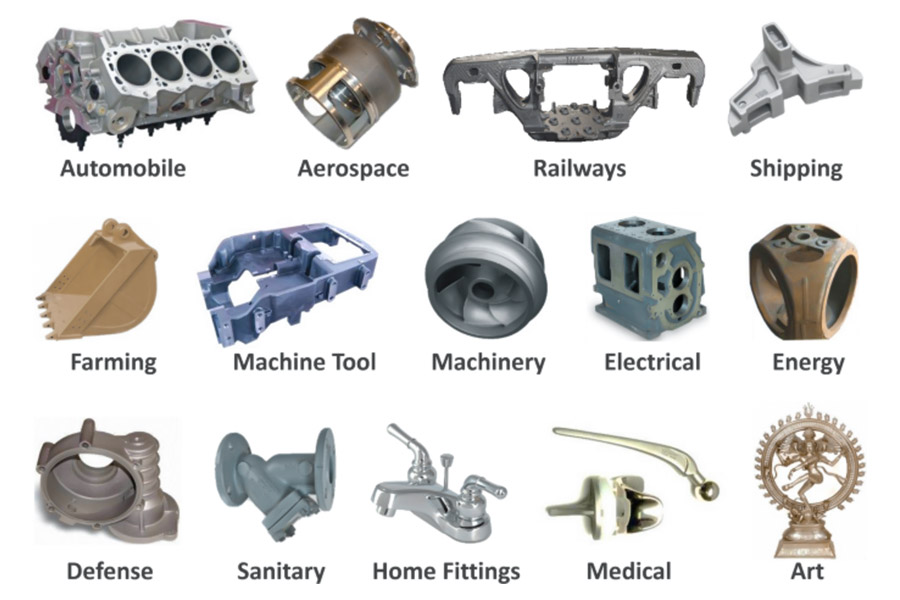

Applications of Aluminum Castings in Numerous Industries

Aluminum castings play an important duty in various industries, specifically in aerospace and vehicle applications. In the automobile market, these castings add to lightweight frameworks and improved gas effectiveness. The aerospace market advantages from their strength-to-weight ratio, which is crucial for efficiency and safety and security.

Automotive Sector Applications

As the vehicle industry significantly looks for to boost performance while decreasing weight, light weight aluminum spreadings have actually become a critical service. These castings are commonly used in various elements, including engine blocks, transmission housings, and suspension parts, as a result of their exceptional strength-to-weight ratio. Aluminum's light-weight nature contributes to enhanced fuel efficiency and general vehicle efficiency. In addition, aluminum castings can be elaborately created, enabling complicated forms that optimize airflow and reduce drag. The product also provides remarkable deterioration resistance, extending the life expectancy of auto components. Makers profit from aluminum's recyclability, aligning with sustainability goals in the industry. Overall, aluminum spreadings stand for a vital innovation in the pursuit of innovative automotive design and effectiveness.

Aerospace Market Utilizes

While the aerospace market requires high performance and integrity, aluminum spreadings supply important benefits that fulfill these rigorous standards. Light-weight yet strong, light weight aluminum castings significantly minimize total airplane weight, improving gas effectiveness and efficiency. They are utilized in various components, including engine real estates, structural components, and landing gear, sustaining complicated layouts that need accuracy and sturdiness. The corrosion resistance of light weight aluminum likewise contributes to longer life span and reduced maintenance costs. Furthermore, advancements in casting technology enable for elaborate geometries and boosted mechanical residential properties, making aluminum castings a preferred choice. As the aerospace field remains to progress, the duty of aluminum spreadings remains pivotal in attaining ingenious options that resolve both safety and effectiveness.

Various Kinds Of Light Weight Aluminum Alloys Used in Casting

When discovering the domain of light weight aluminum spreading, it comes to be necessary to understand the various sorts of aluminum alloys available, each offering distinctive properties matched for different applications. Aluminum alloys are primarily classified right into two groups: functioned and cast alloys - Aluminum Castings. Cast alloys are assigned by a four-digit number system, with the first digit showing the major alloying component

For instance, 1xx.x alloys are pure light weight aluminum, while 2xx.x alloys include copper, enhancing toughness however lowering rust resistance. Alloys such as 3xx.x, that include silicon, visit this page are preferred for their fluidness and low contraction, making them ideal for complex spreadings.

Another usual group, 5xx.x alloys, include magnesium, offering outstanding deterioration resistance and weldability. Each alloy type is picked based on certain efficiency demands, consisting of resistance, weight, and toughness to ecological aspects, making certain superior cause various commercial applications.

Quality Control Measures in Light Weight Aluminum Spreading

Efficient top quality control procedures are important in aluminum casting to guarantee the manufacturing of high-grade components that satisfy sector criteria and customer assumptions. These procedures generally involve a mix of strenuous assessment procedures and standard testing procedures.

During the casting process, operators check critical parameters such as temperature, alloy, and stress make-up to assure uniformity and accuracy. Aesthetic evaluations are conducted to identify surface area defects, while non-destructive screening techniques, like ultrasonic and X-ray evaluations, examine interior integrity without damaging the parts.

In addition, testing for mechanical buildings, such as tensile stamina and solidity, guarantees that the end products have the needed sturdiness and efficiency attributes.

Documents of these quality assurance processes is crucial, as it offers traceability and accountability, permitting manufacturers to address any issues promptly. By implementing comprehensive quality assurance actions, aluminum casting firms can enhance their item reliability and keep customer contentment.

Solutions for Custom-made Aluminum Spreading Solutions

Custom-made light weight aluminum spreading remedies offer tailored design abilities to fulfill details client demands. Making use of advanced spreading methods, these services assure accuracy and performance in the manufacturing process. This mix permits services to accomplish desired end results while optimizing material use and lowering waste.

Tailored Layout Abilities

Tailored design abilities play an important duty in the development of custom-made aluminum spreading remedies, enabling producers to meet particular client needs with precision. By using innovative software and design knowledge, firms can produce complex styles that comply with precise specs. These capabilities make it possible for modification in measurements, weight, and structural integrity, making certain that each spreading aligns perfectly with the intended application. On top of that, producers web link can work together very closely with clients throughout the layout phase, facilitating changes and improvements as needed. This collaborative approach not just enhances item efficiency yet additionally maximizes production effectiveness. Eventually, tailored style capabilities are a vital variable in providing top quality aluminum castings that accomplish distinct industrial demands, thus improving customer satisfaction and promoting lasting collaborations.

Advanced Spreading Techniques

As makers endeavor to boost performance and product high quality, advanced casting strategies have actually become a keystone in the domain of custom aluminum spreading solutions. These methods include techniques such as die casting, sand spreading, and investment casting, each offering distinct benefits depending on the application. Pass away casting, known for its precision and repeatability, is perfect for high-volume manufacturing. Sand casting offers flexibility in design, suiting complicated forms and bigger elements. Financial investment spreading succeeds in achieving intricate details and premium surface area coatings. By leveraging these innovative strategies, manufacturers can create light-weight, sturdy, and high-performance light weight aluminum elements tailored to particular sector needs. Continuous advancements in casting modern technology even more enhance capacities, enabling the manufacturing of even more complicated geometries and improving overall product performance.

Often Asked Inquiries

How Do Environmental Laws Affect Aluminum Spreading Processes?

Environmental laws markedly affect light weight aluminum casting procedures by applying more stringent exhausts requirements, advertising lasting techniques, and urging using environmentally friendly materials. These regulations drive makers to innovate and embrace cleaner technologies in their procedures.

What Are the Usual Problems Located in Aluminum Castings?

Typical problems in light weight aluminum spreadings consist of porosity, shrinking, misruns, chilly shuts, and surface area imperfections. Wisconsin Aluminum Foundry. These issues occur from elements like incorrect temperature level control, inadequate mold and mildew style, or contamination, impacting the overall quality and performance of actors items

Exactly how Is the Recycling Process for Light Weight Aluminum Castings Conducted?

The reusing procedure for aluminum spreadings involves collecting scrap, thawing it in a furnace, getting rid of contaminations, and after that casting the molten check my site light weight aluminum right into new shapes. This method saves energy and reduces waste in production.

What Technologies Are Currently Forming the Future of Aluminum Casting?

Technologies forming the future of light weight aluminum casting consist of innovative 3D printing strategies, automated robotic processes, boosted alloys for improved performance, and sustainable techniques that focus on lowering waste and energy usage in producing processes.

Just how Does the Cost of Light Weight Aluminum Spreading Contrast to Other Products?

Light weight aluminum casting typically offers an affordable expense compared to various other materials, such as steel and plastics. Its lightweight nature and recyclability can result in long-lasting financial savings, making it an attractive option for different applications.

These procedures consist of different methods, such as sand spreading, die casting, and investment casting, each customized to particular applications and demands. Sand casting involves producing a mold from sand and is suitable for huge components, while die spreading makes use of high-pressure shot of molten aluminum into metal mold and mildews for accurate, high-volume production. When exploring the domain name of light weight aluminum casting, it ends up being important to recognize the numerous types of aluminum alloys readily available, each offering distinct residential properties matched for various applications. As manufacturers strive to enhance effectiveness and product high quality, progressed casting strategies have emerged as a keystone in the domain name of personalized light weight aluminum spreading remedies. These strategies incorporate methods such as die spreading, sand spreading, and investment casting, each offering unique advantages depending on the application.